Products

P&S Vision Inspection

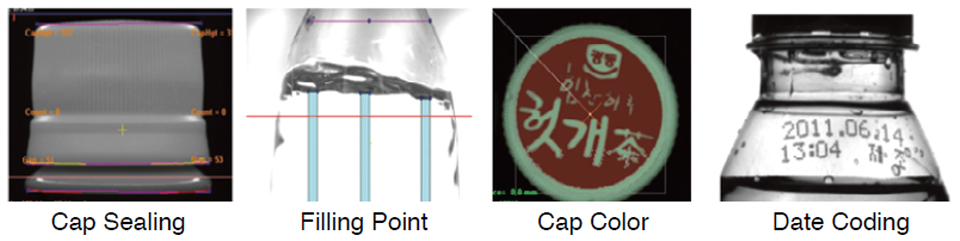

Plastic / Aluminum Cap Seal Inspection Machine

The PS-21C is a new stand-alone model for inspecting cap sealing conditions of food and beverage or medical product bottles. You can inspect rubber vials and cap seals of vials for pharmaceuticals as well as plastic caps for food and beverages, aluminum caps. Optionally, you can add levels, date codes and label inspections, and you can install without changing the conveyor conditions on the shop floor.

Date coding seal checker

The PS-21DC is a control rack built-in checker and it is a linear type inspection equipment. This model is specially designed to inspect the date code printed on the bottom of the can, with a maximum inspection speed of over 1,500 cans per minute. In particular, OCR functionality can be applied to examine incorrectly printed date coding. With special LED lighting, you can inspect not only 2-ply aluminum cans but also 3-ply steel cans without changing the lighting or modifying the program.

Level Inspector

This is a device that inspects the amount of contents, that is, the amount of filling after filling.

Whether the contents are transparent or opaque, accurate level measurement is possible by means of detecting the average value of the filling surface.

Heterogeneous Cap Inspector

This is a device to check whether the cap type of filling bottle is normal.

It is a system to detect whether there is a defect by distinguishing the difference from the normal cap by color, design, and shape of the cap.